Logistics

The Mega-Inliner® System revolutionizes the logistics of non-hazardous and food-grade liquids. Designed for efficiency, hygiene, and sustainability, it replaces traditional tank transport with a smarter, cleaner, and more cost-effective solution.

The New Standard in Liquid Logistics

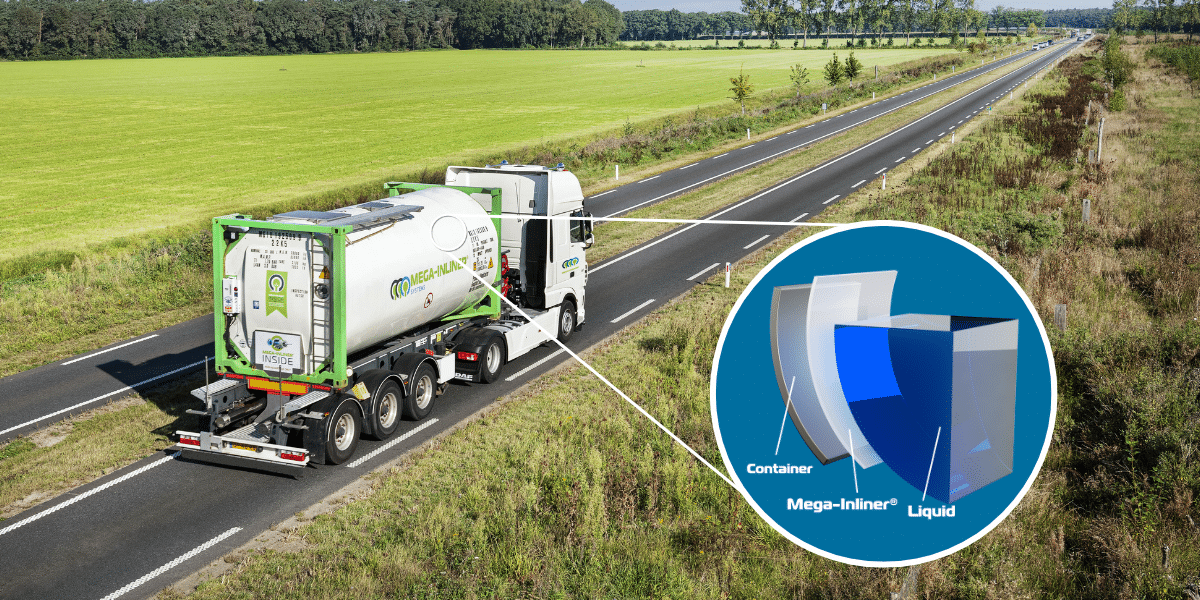

The Mega-Inliner® System combines our patented bag-in-tank technology with our 20ft insulated Mega-Inliner® Tank Container (MTC). Each transport uses a new, single-use Mega-Inliner®, ensuring a fully sealed, contamination-free environment. No cleaning, no cross-contamination, and no product loss. Only efficient, hygienic, and reliable transport from loading to delivery.

Efficiency and Sustainability in Every Flow

Unlike conventional tank containers, the Mega-Inliner® System:

- Eliminates cleaning cycles and wastewater disposal

- Reduces CO₂ emissions by up to 65%

- Minimizes downtime and operational costs

- Improves product quality by avoiding oxidation and (de)saturation

This makes it ideal for transporting beer, juices, dairy, oils, water, chocolate, concentrates, and other non-hazardous liquids safely and efficiently — locally and globally.

We convert all kinds of existing transport solutions

to the Mega-Inliner®

The following benefits apply immediately:

- No cleaning or rinsing

- No cleaning costs

- No empty trips to cleaning stations

- No waiting times

- No chemicals

- Less wear on containers

- Longer container lifespan

- Lighter container possible

- No chemical waste streams

- No water use (up to 2,750 L saved per cleaning)

- No energy for heating cleaning water

- Ready for next load within 30 minutes

- No administration of previous loads

- Lower allocation costs

- Better container utilization

- Fewer empty kilometers

- No rejections due to contamination or product degradation

The following benefits apply immediately:

- Significant less loss of product

- No leakage risk

- No contamination or oxidation

- Temperature-controlled transport (-3°C to +60°C)

- Higher payload & true intermodal compatibility

- Faster loading/unloading

- Reusable container + 100% recyclable liner

- No disposal of large plastic waste/several waste streams

- No CO₂ needed, no cleaning required

- Ready for the next load in 30 minutes

-

Suitable for all food-grade & high-value liquids

- Massively reduced plastic use (from hundreds of kg of drum/IBC liners → to only 15 kg Mega-Inliner® per TEU)

- Far fewer filling operations

- Far fewer unloading operations

- Minimal product waste (no residue left in dozens of separate drums/IBCs)

- No pollution from empty drums or IBCs (no rinsing, no disposal of contaminated packaging)

- Much lower labor costs (one MTC replaces hundreds of drums/IBCs)

- Reduced handling & warehouse movements (less forklift use, fewer manual operations)

- Higher safety for operators (no lifting, cutting, opening, or moving heavy units)

- Lower risk of contamination (single, sealed food-safe Mega-Inliner® protects product quality)

- Improved loading & discharge speed

- Lower transport cost per liter (higher payload and fewer handling steps)

- Significant CO₂ reduction (less packaging, less waste, fewer movements, better efficiency)

- No risk of damaged, dented, or leaking drums/IBCs

- More efficient storage (one MTC replaces an entire pallet rack of individual containers)

-

Ideal for automated, large-volume flows

- Far fewer containers needed ( One Mega-Inliner® replaces 2.5 prepacked box container shipments)

- Much lower transport costs per ton

- Significantly less packaging capital in the supply chain

- Filling on location, closer to the customer

- Reduced handling and warehousing

- Lower CO₂ footprint (less packaging, fewer shipments)

- Lower product damage risk (no pallets, cartons, or individual packs)

- Less product waste (no leftover product in small packages)

-

Higher operational speed (bulk loading/unloading vs. manual handling)

Optimized for Inbound and Outbound Logistics

Because each Mega-Inliner® is single-use, inbound and outbound flows can be combined with different products without cleaning or prior cargo restrictions. This innovation simplifies supply chain management, reduces empty return trips, and improves logistical flexibility.

The Future of Liquid Transport

From breweries, food/drink producers to logistics companies and distributors, industry leaders choose the patented Mega-Inliner® System to meet today’s demands for sustainable, hygienic, and cost-efficient liquid logistics. Experience the benefits of Mega-Inliner your self and get in touch with Coen!

Cleaner. Smarter. More efficient.

FAQ

Mega-Inliner® is a combination of 2 everyday used bulk transport systems, we bring the best of these 2 worlds together for the best solution available on the market in transporting non-hazardous liquids. An environmentally conscious transport system that reduces Co2 emissions enormously and is also extremely cost-efficient. By using the Mega-Inliner System® planning becomes child’s play when connecting Inbound and Outbound flows.

- 100% product quality,

- No degradation

- No oxidation due to closed system when (un)loading

- No (de)saturation – carbonated products

- Temperature control (from -8c to 71c) , cooling or heating

- Lowest product spill/residue per load

- Lowest Co2 footprint possible per Mt product in total supply chain

- No cross-contamination

- No previous cargo restrictions

- No cleaning or rinsing of the tank, saving water, energy, and chemicals

- No empty kilometres or depot costs

- FDA & EU Food approved

- Halal & Kosher

- Mega-Inliner® 100% Recyclable (single source material)

- Aseptic loading, transport, and unloading possible

- Suitable for storage, longer shelf life

- One-man operation, short lead time

- No people on top of or in the tank.

- Connecting inbound and outbound logistics

Depending on the current supply chain we can be competitive with all. If you are transporting ready-to-drink in bottles now, the impact of using our system is huge, but changing the supply chain takes more time, switching from conventional tank container or flexitank to Mega-Inliner® is easy and gives you the benefits immediately. All other IBCs, Drums, kegs, etc are somewhere in the middle.

By using the Mega-Inliner® System it is possible to go directly to the next loading location without the need for cleaning between each load. Therefore, costs such as driver wages, cleaning costs and waiting time are being saved. Because there will be no residue left behind in the tank all costs of product being wasted are eliminated. Due to our Mega-Inliner®, your product will be shipped in a clean and closed environment and therefore there is no chance of cross-contamination or other problems.

By using the Mega-Inliner® System your Co2 emission will be reduced by a minimum of 30%. The Mega-Inliner® is 100% recyclable and cleaning of the Tank Container becomes obsolete. Our system makes it possible to connect Inbound and Outbound logistics by simply removing the Mega-Inliner® after each load, this results in no empty kilometres to and from cleaning stations, wastage of valuable (drinking) water belongs to the past (saving ± 2,500 litres per cleaning), no chemicals for cleaning are necessary. Ship your foodstuff or other non-hazardous liquids in bulk globally and pack locally save up to 60% on transport costs and reduce a minimum of 30% on your Co2 emission.