Smarter, Faster, Safer: The Evolution of Liquid Transport

When transporting liquid products in conventional tank containers, several key challenges can compromise your goods’ safety. Many companies do not realize that their transportation methods contribute to risks such as cross-contamination, oxidation, (de)saturation and inefficiencies in the supply chain. These issues can significantly impact the quality of your product, the efficiency of your logistics processes, your environmental footprint, and costs. Fortunately, Mega-Inliner® offers an innovative solution that addresses these problems while helping your business save time, money, and energy (Co2).

The pitfalls of conventional tank containers

One of the biggest problems with conventional tank containers is the need for thorough cleaning after each load. Companies often encounter persistent issues such as pitting (corrosion) and wear and tear on the inside of the tank. This wear allows microscopic residues from previous loads to remain, even after extensive cleaning. This can lead to serious cross-contamination, where residues from one product unintentionally come into contact with the next product being transported. This is especially concerning for food or pharmaceutical products, where quality can be seriously compromised.

Over time, often within 20 years, a conventional tank becomes unusable due to the harsh cleaning processes involving corrosive chemicals. Not only does this mean that new tanks must be purchased regularly, but the environmental impact of waste and chemical use is also substantial.

The solution: The Mega-Inliner® System

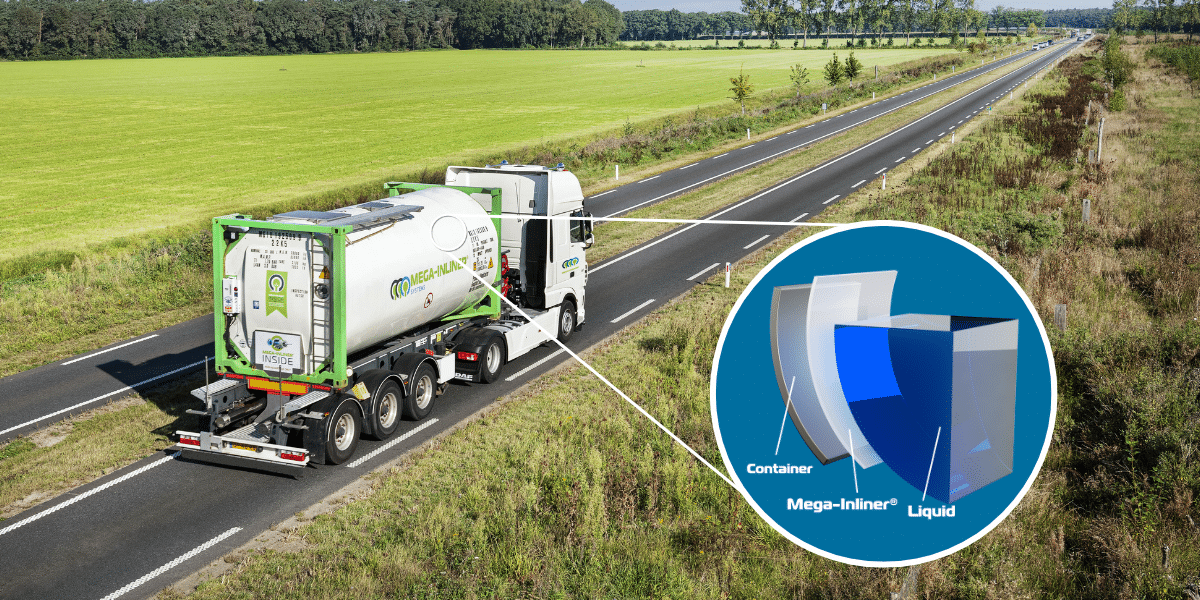

At Mega-Inliner®, we address these problems with a revolutionary system. Instead of cleaning the tank after each load, the Mega-Inliner® System installs a bag-in-tank (Mega-Inliner®) for every new load. This means that the tank container never comes into direct contact with the liquid. As a result, cross-contamination is completely prevented, and issues such as oxidation and (de)saturation are eliminated.

Thanks to this innovative approach, cleaning processes are no longer necessary. You no longer need to worry about using aggressive cleaning agents, the wear and tear on the tank container, or the waste of water and energy associated with conventional cleaning methods. This not only makes the Mega-Inliner® System safer for your products but also more sustainable for the environment.

Flexibility in load planning

With conventional tank containers, it’s often impossible to load certain products consecutively. Some products require extensive cleaning procedures before the next load can be added. This means a significant amount of time, energy, and CO2 emissions are wasted repositioning empty containers to special cleaning facilities and then back to new loading locations. This process not only adds extra costs but also increases the environmental impact of your logistics operations.

With Mega-Inliner, this problem is a thing of the past. Since a new fresh Mega-Inliner® bag is installed with each new load, you can transport any conceivable non-hazardous liquid consecutively without the need for cleaning or repositioning. This gives you maximum flexibility in load planning, saving you time and money, while also significantly increasing transportation efficiency.

Reduction of product waste

Another key advantage of the Mega-Inliner® System is the reduction of product waste in the supply chain. The Mega-Inliner® has a completely smooth surface, ensuring that no product residues remain after unloading. Using air pressure, every last drop of product is effectively discharged from the tank container, minimizing waste. This is especially important in industries like food and beverage, where product loss has a direct impact on profitability and sustainability.

Sustainability and cost savings

The Mega-Inliner® System not only provides benefits in terms of product safety and efficiency but also offers significant cost savings and a reduced environmental footprint (60%). Without the need for cleaning and repositioning processes, you reduce operational costs and lower greenhouse gas emissions. Additionally, the system extends the lifespan of your tank containers since they are no longer exposed to the corrosive chemicals used in traditional cleaning methods.

Conclusion

With the Mega-Inliner® System, you can optimize your transport logistics. No more concerns about cross-contamination, oxidation, or (de)saturation of your products. Your supply chain becomes more efficient, sustainable, and flexible, all while ensuring the safety of your goods. Choosing Mega-Inliner® means opting for an innovative solution that benefits both your operations and the environment.

Contact us for more information and business opportunities!

Mega-Inliner® is a combination of 2 everyday used bulk transport systems, we bring the best of these 2 worlds together for the best solution available on the market in transporting non-hazardous liquids. An environmentally conscious transport system that reduces Co2 emissions enormously and is also extremely cost-efficient. By using the Mega-Inliner System® planning becomes child’s play when connecting Inbound and Outbound flows.

- 100% product quality,

- No degradation

- No oxidation due to closed system when (un)loading

- No (de)saturation – carbonated products

- Temperature control (from -8c to 71c) , cooling or heating

- Lowest product spill/residue per load

- Lowest Co2 footprint possible per Mt product in total supply chain

- No cross-contamination

- No previous cargo restrictions

- No cleaning or rinsing of the tank, saving water, energy, and chemicals

- No empty kilometres or depot costs

- FDA & EU Food approved

- Halal & Kosher

- Mega-Inliner® 100% Recyclable (single source material)

- Aseptic loading, transport, and unloading possible

- Suitable for storage, longer shelf life

- One-man operation, short lead time

- No people on top of or in the tank.

- Connecting inbound and outbound logistics

Depending on the current supply chain we can be competitive with all. If you are transporting ready-to-drink in bottles now, the impact of using our system is huge, but changing the supply chain takes more time, switching from conventional tank container or flexitank to Mega-Inliner® is easy and gives you the benefits immediately. All other IBCs, Drums, kegs, etc are somewhere in the middle.

By using the Mega-Inliner® System it is possible to go directly to the next loading location without the need for cleaning between each load. Therefore, costs such as driver wages, cleaning costs and waiting time are being saved. Because there will be no residue left behind in the tank all costs of product being wasted are eliminated. Due to our Mega-Inliner®, your product will be shipped in a clean and closed environment and therefore there is no chance of cross-contamination or other problems.

By using the Mega-Inliner® System your Co2 emission will be reduced by a minimum of 30%. The Mega-Inliner® is 100% recyclable and cleaning of the Tank Container becomes obsolete. Our system makes it possible to connect Inbound and Outbound logistics by simply removing the Mega-Inliner® after each load, this results in no empty kilometres to and from cleaning stations, wastage of valuable (drinking) water belongs to the past (saving ± 2,500 litres per cleaning), no chemicals for cleaning are necessary. Ship your foodstuff or other non-hazardous liquids in bulk globally and pack locally save up to 60% on transport costs and reduce a minimum of 30% on your Co2 emission.