For decades, the global beer and beverage industry has operated on a simple premise: produce your own brands, in your own breweries, using your own packaging lines, and distribute them through your own networks.

In an era when shipping packaged, ready-to-drink beverages was the only viable option, this model made perfect sense. It shaped investment strategies, supply chains, and even corporate identities.

Yet it also created something far less sustainable: Massive structural overcapacity.

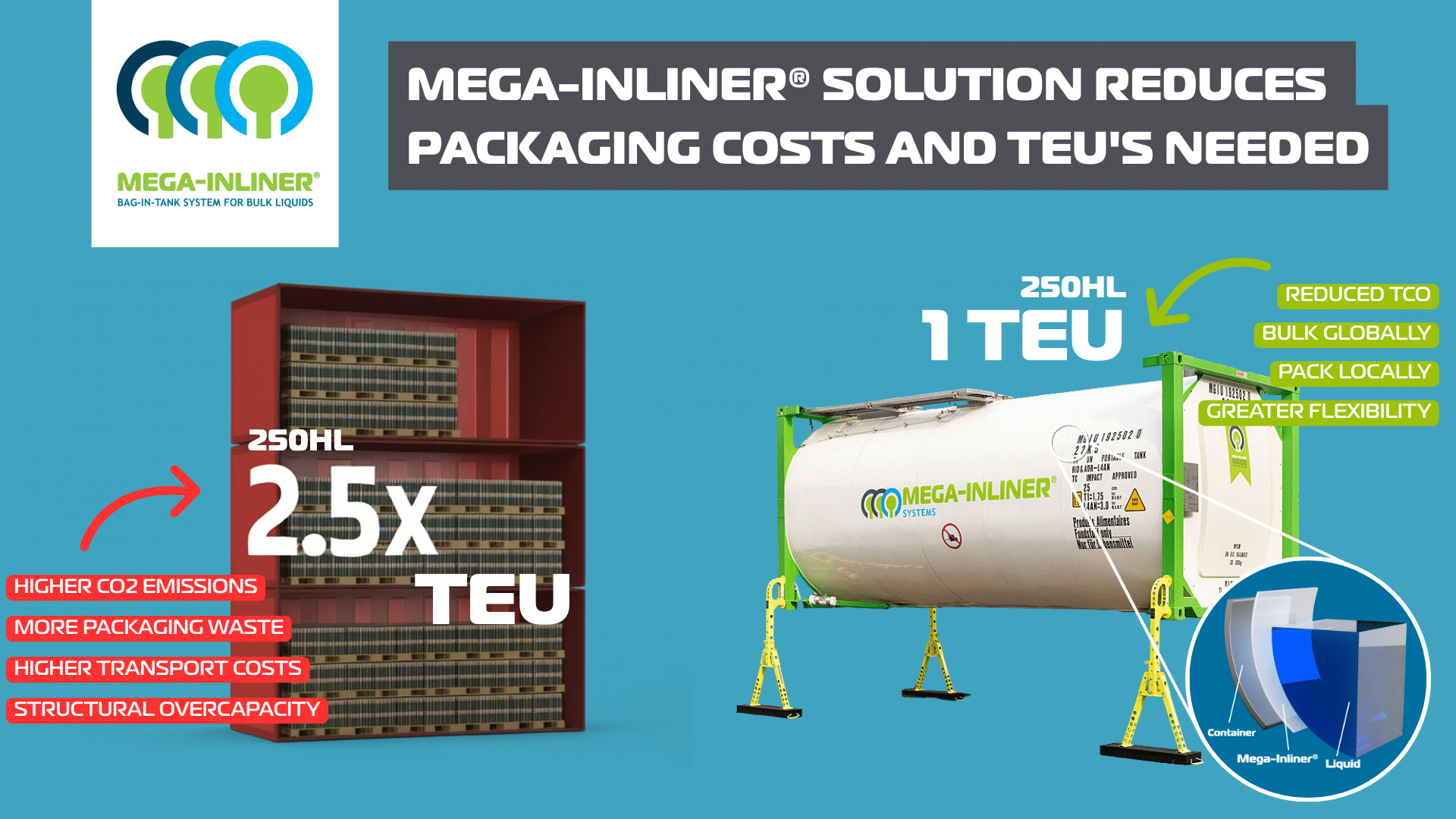

Breweries expanded. Packaging lines multiplied. Distribution networks stretched across continents. All of this was justified by the need to ship finished product, despite the fact that an average container could only move around 100 HL per TEU when shipping packaged goods. The result was a system optimized for a world that no longer exists.

Today, as demand pressures grow and margins shrink, we’re watching the cost of maintaining this “self-contained” model becoming harder to justify.

A New Reality: Bulk Technology Has Outpaced the Old Logistics Logic

The landscape has fundamentally changed.

Carrier capacities have surged, global markets are more dynamic than ever, and—most importantly—bulk transport technology has advanced dramatically. What once required expensive, rigid, and operationally complex solutions like ISO tanks (with their cleaning, quality risks, and costly empty returns) can now be done safely, efficiently, and with far more flexibility.

The Mega-Inliner® System transforms the economics entirely.

For the first time, beverage producers can ship their products in bulk, in any refitted ISO tank container, without cargo restrictions, while safeguarding the quality and integrity their brands require. The operational efficiencies are compelling but the strategic implications are even greater.

Because if shipping finished goods is no longer a must…

Why maintain such extensive fixed packaging capacity?

If you can ship bulk economically….

Why lock yourself into a production footprint designed for a past era?

The Rise of Co-Packers: Flexibility Becomes the Competitive Advantage

As bulk logistics becomes more economical, local co-packers from specialist operators to global players such as Refresco are assuming a central role in the value chain. They offer precisely what today’s beverage market demands: flexibility, multi-brand capability, and packaging-on-demand.

Instead of producing and packaging everything at origin, brands can now:

- Ship bulk globally

- Leverage flexible local packaging capacity

- Reduce capital intensity

- Respond rapidly to shifting market dynamics

This shift is more than operational, it is philosophical.

Producers that once took pride in doing everything in-house are now recognizing that flexibility, not ownership, determines competitiveness.

The Industry Is Transforming, with Mega-Inliner® as the Enabler

The beverage sector is undergoing a structural transition similar to what many other industries have already experienced: a move from fixed, capital-heavy systems to agile, demand-driven networks.

Declining consumption volumes only accelerates the urgency.

Within this context, Mega-Inliner® represents far more than a logistics upgrade.

It is the enabling technology behind a new production and distribution philosophy: Ship bulk globally >> Pack Locally, Reduce waste, Increase flexibility and Protect margins.

What started as an incremental innovation has evolved into a strategic necessity.

The Breakup Was Inevitable

As François Sonneville rightly notes in his latest article, “breaking up” with legacy capacity structures is difficult. These systems were built with pride, vision and significant investment. But today’s economic realities tell a different story. Markets are contracting, costs are rising, and long-held assumptions no longer apply.

The industry is being reshaped quietly but decisively by solutions that eliminate the constraints of the past.

Mega-Inliner® stands at the center of this transformation, offering producers the ability to adapt, compete, and thrive in the next era of beer and beverage manufacturing.

Let’s Build the Beverage Supply Chain of the Future — Starting Today

Mega-Inliner® helps you to:

✔ Reduce dependency on fixed packaging capacity

✔ Unlock global bulk-shipping capabilities

✔ Leverage local co-packing networks

✔ Lower operational and capital costs

✔ Increase supply chain agility and resilience

Whether you want to explore a pilot shipment, model the financial impact, or redesign your global supply chain, our team is ready to support you.

Connect with us to discuss how Mega-Inliner® can transform your logistics, reduce costs, and future-proof your production strategy.

👉 Schedule a strategic consultation

👉 Request a technical demonstration

👉 Explore partnership opportunities with co-packers and global shippers

The industry is changing. The economics are changing.

Now is the moment to act.

Mega-Inliner® is a combination of 2 everyday used bulk transport systems, we bring the best of these 2 worlds together for the best solution available on the market in transporting non-hazardous liquids. An environmentally conscious transport system that reduces Co2 emissions enormously and is also extremely cost-efficient. By using the Mega-Inliner System® planning becomes child’s play when connecting Inbound and Outbound flows.

- 100% product quality,

- No degradation

- No oxidation due to closed system when (un)loading

- No (de)saturation – carbonated products

- Temperature control (from -8c to 71c) , cooling or heating

- Lowest product spill/residue per load

- Lowest Co2 footprint possible per Mt product in total supply chain

- No cross-contamination

- No previous cargo restrictions

- No cleaning or rinsing of the tank, saving water, energy, and chemicals

- No empty kilometres or depot costs

- FDA & EU Food approved

- Halal & Kosher

- Mega-Inliner® 100% Recyclable (single source material)

- Aseptic loading, transport, and unloading possible

- Suitable for storage, longer shelf life

- One-man operation, short lead time

- No people on top of or in the tank.

- Connecting inbound and outbound logistics

Depending on the current supply chain we can be competitive with all. If you are transporting ready-to-drink in bottles now, the impact of using our system is huge, but changing the supply chain takes more time, switching from conventional tank container or flexitank to Mega-Inliner® is easy and gives you the benefits immediately. All other IBCs, Drums, kegs, etc are somewhere in the middle.

By using the Mega-Inliner® System it is possible to go directly to the next loading location without the need for cleaning between each load. Therefore, costs such as driver wages, cleaning costs and waiting time are being saved. Because there will be no residue left behind in the tank all costs of product being wasted are eliminated. Due to our Mega-Inliner®, your product will be shipped in a clean and closed environment and therefore there is no chance of cross-contamination or other problems.

By using the Mega-Inliner® System your Co2 emission will be reduced by a minimum of 30%. The Mega-Inliner® is 100% recyclable and cleaning of the Tank Container becomes obsolete. Our system makes it possible to connect Inbound and Outbound logistics by simply removing the Mega-Inliner® after each load, this results in no empty kilometres to and from cleaning stations, wastage of valuable (drinking) water belongs to the past (saving ± 2,500 litres per cleaning), no chemicals for cleaning are necessary. Ship your foodstuff or other non-hazardous liquids in bulk globally and pack locally save up to 60% on transport costs and reduce a minimum of 30% on your Co2 emission.